110 ton injection machine

2019-06-11By saisaer968 Views

The brief introduction of 110 ton injection machine

- Place of Origin: China

- Brand Name:saisaer

- Model Number:110ton

- Driving motor:servo

- Voltage:3phase

- Delivery time:25days

- Suitable material:confirm when order

- Payment way: TT

Our injection machine series

- 1.Variable pump series injection machine

- 2.Precision servo system injection machine

- 3.PET specialzed injection machine

- 4.High speed thin wall injection machine

- 5.PPR/PE pipe fitting specialized injection machine

- 6.PVC powder specialized injection machine

- 7.Double color injection machine

- 8.Bakelite injection machine

Our injection machine standard accessories

- 1.Mold Clamps

- 2.Adjustable mechamical shockproof pad

- 3.Thermal couple

- 4.Heating ring

- 5.Sealing ring

- 6.Contactor

- 7.Tool sets cabinet

Our injection machine optional accessories

- 1.Electric eye

- 2.Robot arm

- 3.Automatic feeder

- 4.Hopper dryer

- 5.Dehumidifier

- 6.Water cooler

- 7.Magnetic force shelving

- 8.Hydraulic oil pressure core pulling device

- 9.Mold temperature controller

- 10.Hydraulic safety interlock

- 11.Energy-saving type variable delivery pump

The parameters of 110 ton injection machine

|

|

SS110/358 |

| Injection unit |

unit |

358 |

| A |

B |

C |

| Screw diameter |

mm |

35 |

38 |

42 |

| Screw L/D |

L/D |

22.8 |

21 |

19 |

| Shot volume |

cm³ |

163 |

192 |

235 |

| Injection weight(ps) |

g |

148 |

175 |

213 |

| Injection rate |

cm³/s |

90 |

104 |

128 |

| Injection pressure |

Mpa |

219 |

18% |

158 |

| Screw speed |

rpm |

205 |

| Clamping unit |

|

|

| Clamping force |

KN |

110 |

| Toggle stroke |

mm |

350 |

| Space between tie-bars(W*H) |

mm |

370*370 |

| Max.mould thickness |

mm |

380 |

| Min.mould thickness |

mm |

150 |

| Ejector stroke |

mm |

100 |

| Ejector tonnage |

KN |

30 |

| others |

|

|

| Max.pump pressure |

Mpa |

16 |

| Motor power |

Kw |

12 |

| Heater power |

Kw |

7.55 |

| Machine dimension |

m |

4.2*1.2*1.79 |

| Oil tank capacity |

L |

190 |

| Machine weight |

Ton |

3.2 |

The parts brand of 110 ton injection machine

| Item |

part name |

brand |

original place |

| 1 |

computer |

EST/Techmation |

Taiwan |

| 2 |

contactor |

Schneider/Simens |

France/Germany |

| 3 |

breaker |

Schneider/Omoron |

Frane/Japan |

| 4 |

displacement transducer |

NOVO/JIESA/Jefran |

Germany/USA/Italy |

| 5 |

travel switch |

Schneider/Simens |

France/Germany |

| 6 |

servo motor |

Feishi/Inovance/Haitian |

China |

| 7 |

servo driver |

hunter/Inovance/Haitian |

China |

| 8 |

hydraulic pump |

Sunny/Eckerle/Sumitomo |

Germany/Japan |

| 9 |

direction valve |

Vickers/Tokyokeiki/Yuken |

USA/Japan/Taiwan |

| 10 |

preformed hydraulic motor |

Zhongyi/Staffa/Intermot |

China/Italy |

| 11 |

seal components |

hallite/Trelleborg |

England/Swithland |

Note:all the item marked with bold and underline is the standard brand part.

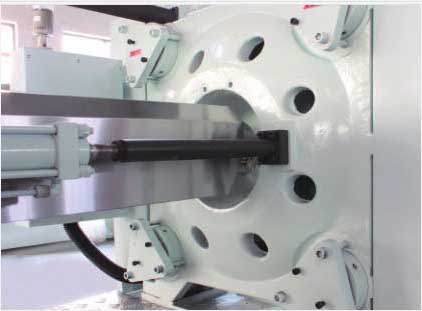

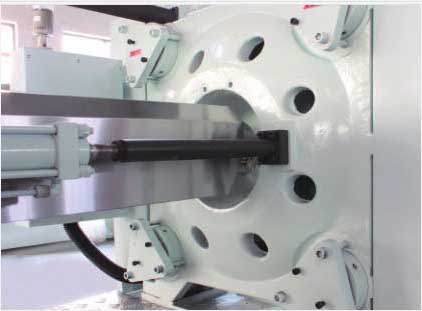

our injection machine structure

clamping part

- 1.The drawbar is hard chrome-plated and resistant to abrasion and corrosion.

- 2.The bottom of the two plates has an adjustable diagonal block structure, which is easy to adjust after wear, thus extending the service life of the machine.

- 3.Automatic centralized lubrication for machine maintenance.

- 4.With synchronous gear shaping, it can be used to adjust the tooth type automatically.

- 5.The clamping position gauge is connected with the thrust to make it easier to adjust the mold protection position.

- 6.Optimized design of the hinge mechanism of the machine, the opening and closing mode is stable and fast, and the service life is long.

shot part

- 1.Double guide guide to improve injection accuracy.

- 2.High speed hydraulic motor.

- 3.Injection, pressure holding pressure closed circuit control, back pressure precision control.

- 4.The structure of the screw barrel is disassembled and easy to replace.

- 5.low-speed high-torque hydraulic motor drives the screw to rotate, and the plasticizing performance is excellent.

- 6.Optimized design of screw raw materials is widely used.

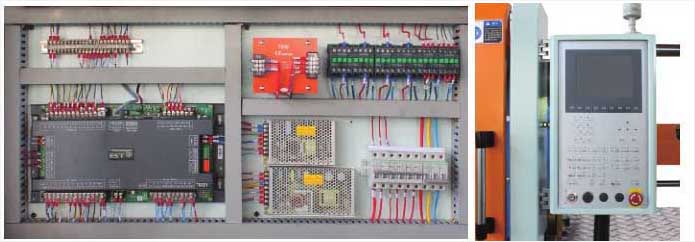

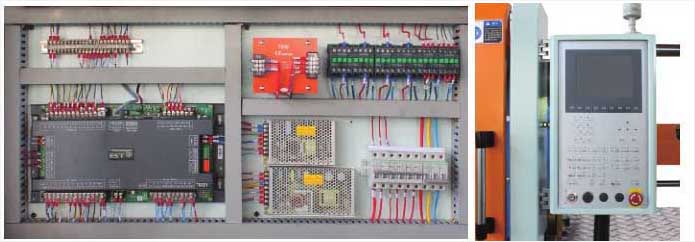

electrical part

The controller uses a special computer for injection molding machine and supports the following functions.

- 1.Panel operator interface supports multiple languages.

- 2.The system unit adopts dual-core microprocessor with high speed, anti-noise and low power consumption.

- 3.USB interface can update or backup system parameters.

- 4.Built-in Ethernet interface, easy to connect.

- 5.Intelligent maintenance page reminder function, provide multi-screen warranty maintenance instructions and tips.

- 6.Graphing pressure, speed, end point, and pressure pressure curve graphic display.

- 7.It has 120 sets of modification records and 120 sets of alarm record functions, which is convenient for data search when abnormal conditions occur.

- 8.The computer starts its own software and hardware detection function and the mechanical fault alarm function.

- 9.I/O analog function, which can realize on-line simulation of input/output points, easy to find wiring and self-detection. The I/O fault point steering function enables software to replace hardware functions.

- 10.Support the simultaneous monitoring of multiple machine controllers through the office computer, establish a dedicated web system, web browsing web pages, company personnel can plan resources in HTML according to different production processes.

- 11.User-friendly design of the operation panel, can be rotated 90 degrees, more convenient for people to operate.

- 12.Servo drive can realize various control methods such as digital control and analog quantity control to meet diverse needs.

- 13.Standard closed-loop monitoring device such as mode-adjusting electric eye, inspection electric eye, speed measuring electric eye, etc.

hydraulic system

- 1.Adopt Taiwan valve block.

- 2.Hydraulic circuit design meets international safety standards.

- 3.Oil temperature is automatically read.

- 4.The pipeline is not welded, durable and reliable, easy to maintain.

- 5.Use well-known hydraulic components.

servo system

- 1.fast response

Servo drive responds quickly and has a 50% faster start-up time than traditional injection molding machines

- 2.oil temperature is constant

The servo motor outputs hydraulic oil proportionally to avoid excessive heat generation. The hydraulic oil does not even need to be cooled, achieving significant water saving.

- 3.Excellent molding stability

Servo drive system, pressure, flow using closed-loop control, compared to the traditional injection molding machine, molding repeatability is significantly improved.

- 4.substantial energy saving

Under the same conditions, energy saving is 20%-80% compared with traditional injection molding machines.

- 5.Environmental protection

The whole machine runs with low noise.