1000mm PVC Sheet Extrusion Production Line

2020-09-23By saisaer244 Views

1.The brief introduction of 1000mm PVC Sheet Production Line

- Raw Material:PVC powder

- Main extruder model:SJSZ65/132

- Width of Sheet:1000mm

- Thickness of Sheet:0.3-1.5mm

- Line speed:5m/min

- Max.capacity:180kg/h

- Voltage:3phase 380v 50Hz

- Delivery time:50days

- Payment way: TT

2.The Composition and price of 1000mm PVC Sheet Production Line

| Item No |

Name |

Qty |

Price |

| ① |

Screw loader for PVC powder and metering feeder |

1set |

|

| ② |

PVC sheet extrusion line |

|

|

|

SJSZ65/132 conical twin screw extruder |

1set |

|

|

PVC sheet T-die 0.3mm-1.5mm |

1set |

|

|

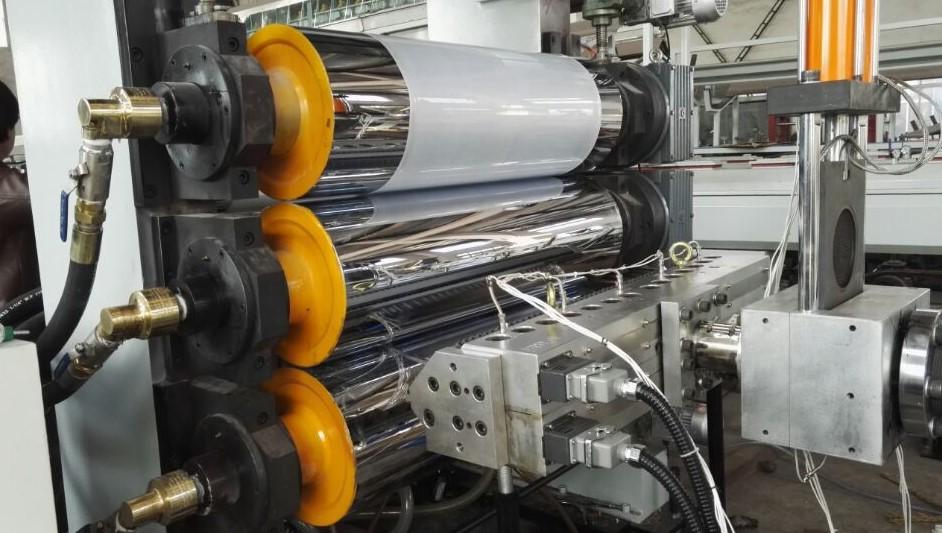

SZ1200 upright rolling machine with three rollers |

1set |

|

|

SL1200 haul off cooling stack with cutter |

1set |

|

|

Double edge trimming coiler |

1set |

|

|

Double station winder |

1set |

|

| Optional equipment |

| ③ |

ZD-600 screw type loader for PVC powder |

1set |

|

| ④ |

SRL-Z200/500A mixing machine |

1set |

|

3.The main technical parameters of PVC 1000mm sheet exrusion producion line

3-1.Automatic loader and metering loader for PVC powder

| Hopper volume |

150L |

| Conveying capacity |

500kg/h |

| weight |

100kg |

| Screw diameter |

100mm |

| motor |

1.5KW |

3-2.SJZ-65/132conical double screw extruder

| Screw diameter |

65/132mm |

| Material of barrel and screw |

38GrMoAlA Nit iding layer thickness 0.5mm-0.7mm |

| Screw effective length |

1440mm |

| Rotate speed |

36.5rpm |

| Main electromotor power |

37KW |

| Main electromotor rotate speed |

1440rpm |

| Auto feeding equipment |

transducer 1.5KW |

| Vacuum exhaust |

2.2KW |

| Extruding output |

240kg/hr |

| Heating segments |

4zones |

| Heating power |

24KW |

| Center height |

1000mm |

| Power of cooling blower |

0.25KW*3 |

| Main motor |

SIEMENS |

| Temperature controller |

RKC |

| Contractor |

SIEMENS |

| Switch |

DELEX |

| inverter |

SINEE |

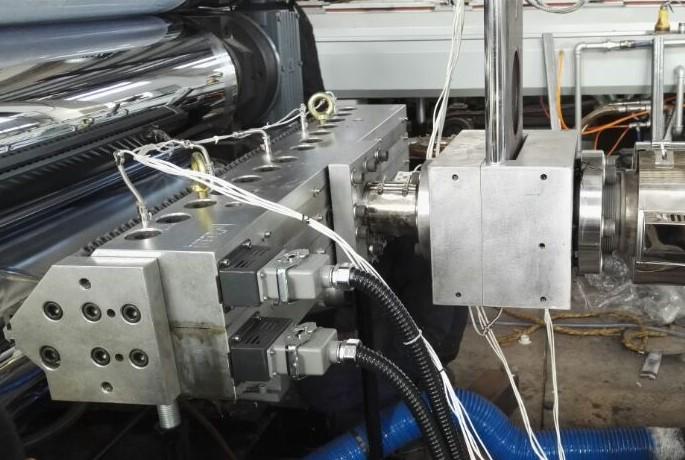

3-3.PVC sheet T-Die 1150

| Width of mould chasm |

1150mm |

| Max. hatch of mould |

producing sheeting with thickness 1.5mm |

| Min. hatch of mould |

producing sheeting with thickness0.3mm |

| Heating power |

2KW/zone |

| Heating zone |

6zone |

| Power supply |

3phase AC 380V/50Hz |

| The mould is produced by high quality of alloy forger |

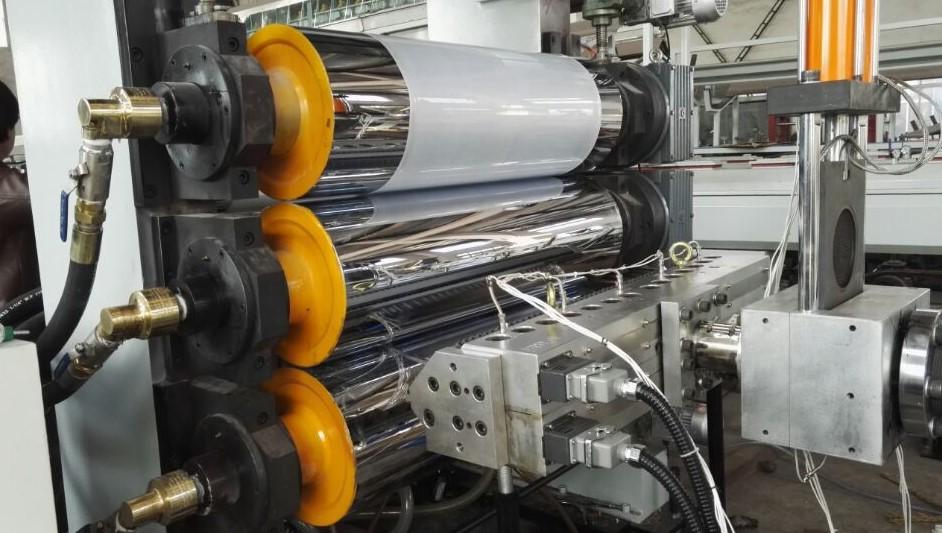

3-4.SZ1200 Caliberating with three roller

| Feeding type |

With feeding roller |

| Max. speed |

10m/min |

| Height of center |

1000mm |

| Frame |

It has high rigidity, welding by profile steel. The whole upright frame is made up of two wall plate and tip joint and the base. Each fixing section is worked on with mechanical process, in order to ensure the fixing precision |

| Driving system |

It adopts separate roller driving. There is a gear down box collocated for each roller. It adopts bevel wheel and worm wheel in the gear box, so that it has stable running, lower noises, high efficiency, compact structure.

Power of driving: Up roller: 1.5KW Mid roller:1.5KW Down roller:1.5KW |

| Specification of Roller |

Diameter of Roller Up roller:400mm Mid roller:400mm Down roller:400mm

The surface of roller is quenched up to HRC45,quenching level:3-5mm

Chromeplate level for roller: t=0.10-0.15

The roller has screwy inner cavity, with 6 head.

Bearing group: adopts double row cylindrical-roller bearing

The base of bearing is cast steel with high rigidity, treated with temper. It is bifid structure, so that it is easy to change the roller quickly. |

| Adjusting unit for the roller gap |

Bevel direct adjusting

The roller gap is kept by screw mandrel, and lifting by motor |

| moving unit |

The whole moving unit includes driving system, roller lifting unit, etc.

Power of Motor: 1.5KW

Adopts bipolar gear down box to drive supply stable running. |

| Electric control box |

Separate electric control box with AC contactor of SIEMENS

Separate control of three rollers with inverter of ABB |

3-5.SL1200 Haul off cooling shelf with side cutter

| Power of Motor |

1.5Kw |

| Power supply |

3phase AC 380V/50Hz |

| Diameter of haul off roller |

200mm |

| The active roller of Haul off is made of rubber |

| Water cooling and air cooling |

| The passive roller of haul off has the effective lifting height of 40mm |

| The double side saw cutting blades cut the redundant sheets effectively, in order to get the required width of sheets. |

| The electric control box is placed with the three rollers electric control box together |

| Diameter of film covering roller |

180mm |

| The length of roller |

1200mm |

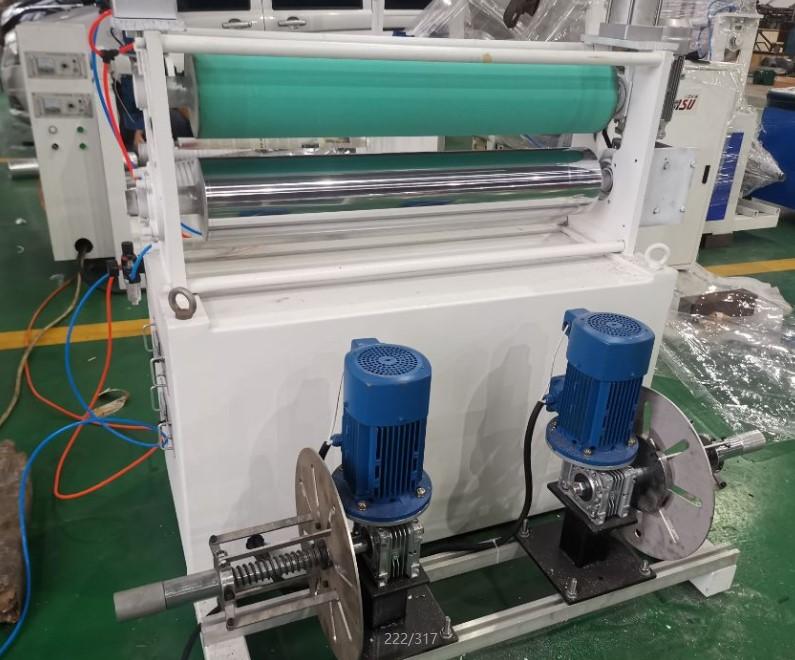

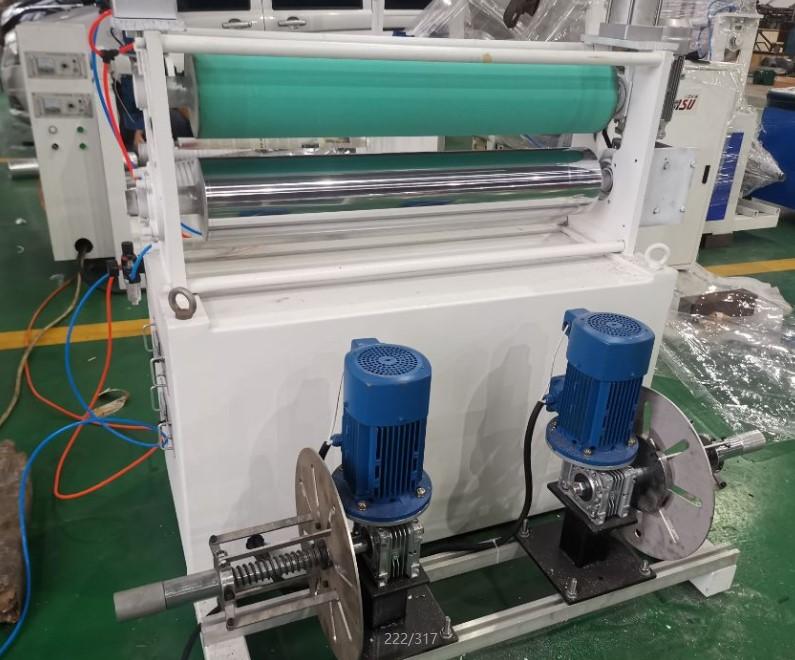

3-6.Winder

| Max.diameter of roller |

450mm |

| The max.width of PVC sheet |

1000mm |

| Power of rotating motor |

1.5Kw |

4.The axuiliary machine for PVC sheet extrusion line(optional)

4-1.ZD-600 Screw type loader for PVC powder

| Loading motor power(KW) |

1.5 |

| Loading tube diameter(mm) |

110 |

| Loading output(kg/h) |

600 |

| Loading height(m0 |

2.5 |

| Tank volume(kg) |

150 |

4-2.SRL-Z 200/500A Mixing Machine

| SRL—Z200/500 |

Heating/Cooling mixing |

| Total capacity(L) |

200/500 |

| Effective capacity(L) |

150/375 |

| Mixing paddle speed (r/min) |

860/130 |

| Heating/cooling method |

Self-friction/ Water cooling |

| Mixing time |

8-12 min/pot |

| Motor power (KW) |

45/7.5 |

| Dimension(mm) |

3580/2540/2270mm |

| Weight(kg) |

2500 |

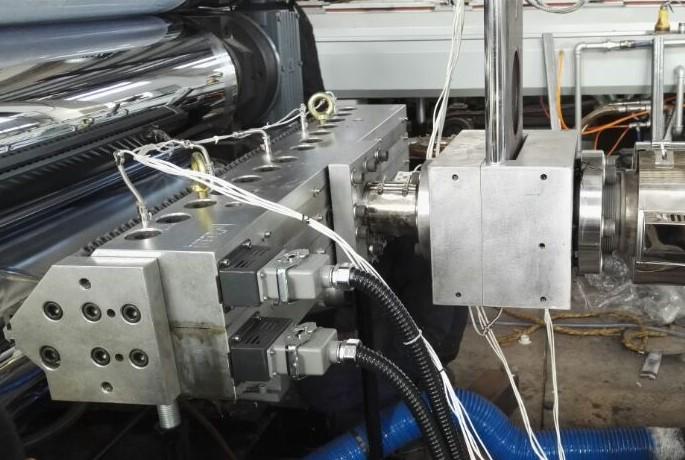

5.More pictures of PVC sheet extrusion production line for reference.

6.The video of PVC sheet extrusion line